After 25 years, we re-made the dickie bird mold.

First and foremost, 25 years ago, Ifailed to flip the design to make our dickie bird face the same way as the original. Many real badges exist in multiple versions, and they often face different directions, so it is an authentic variation – but I still remember the acute pang of remorse when I noticed in the first test pour what I had done. I have not repeated that error in the succeeding years (well, perhpas once).

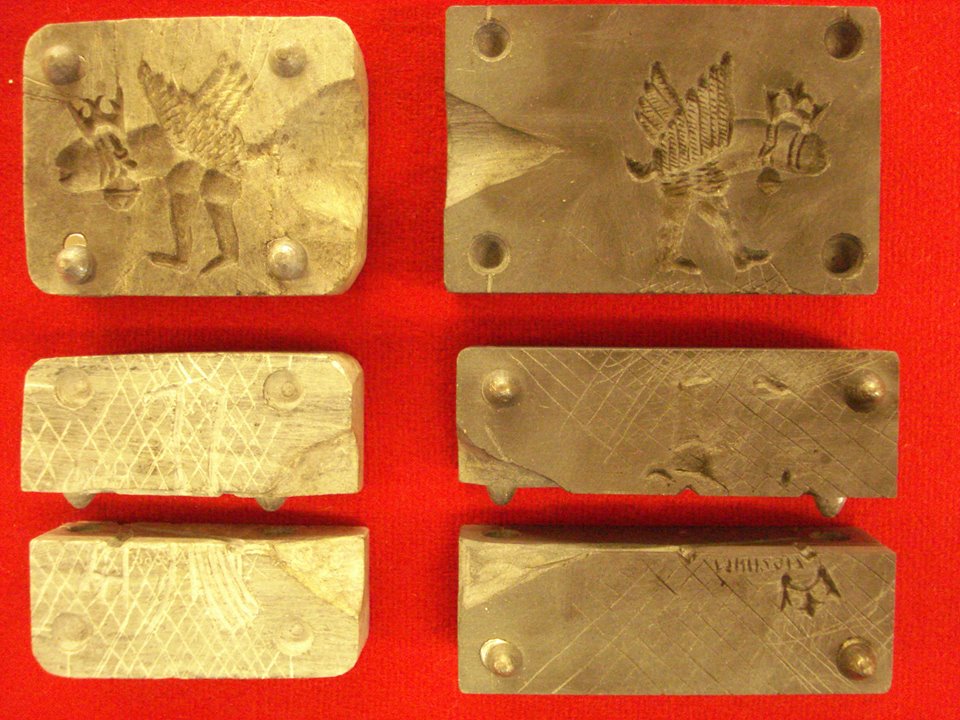

We both have much better control of the metal flow than when we started, and the new mold only required thickening in a couple of places that were necessarily thin in the front or fragile, in contrast to the old mold, to which I added ribs just to make it cast because the mold cavities were not deep enough.

Most embarrassingly, the molds reveal the dreadful truth of the gating on the first bird – the tail serves as part of the sprue. Between the unconventional arrangement and the very short and wide sprue, the castings frequently had to be rejected because one poured back the tail as well as the unneeded metal. Alternatively, one let the metal solidify in the wide gate, and the mold got hotter and hotter, and hotter. The new mold is far better behaved.

The old bird is on the left; the new one on the right. The new one corrects/ improves a number of issues.